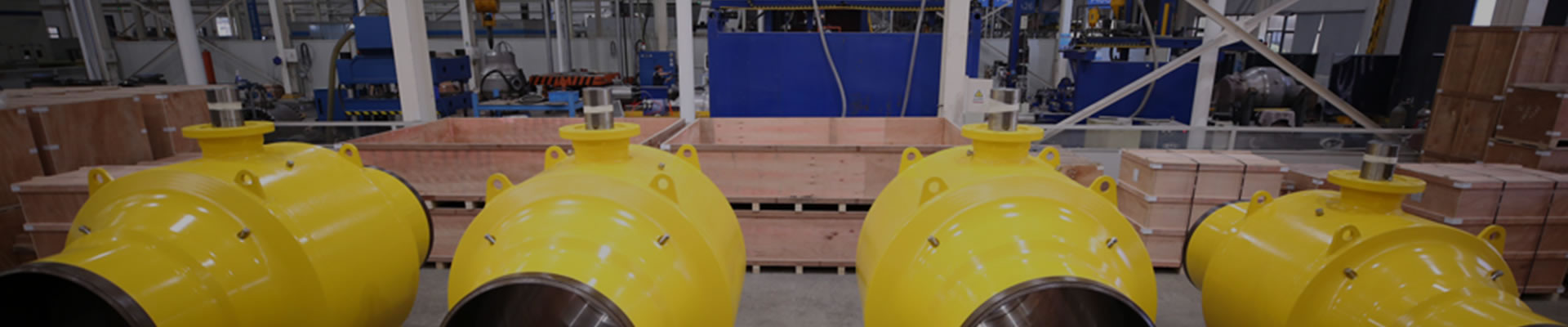

Cryogenic Globe Valve

- Pressure Rating

- CL150~CL2500

- Connection

- RF, RTJ, BW

- Design Standard

- BS 1873

- Material

- A216-WCB (Carbon Steel), A217-WC6 (1-1/4Cr-1/2Mo), A217-WC9 (2-1⁄4Cr–1Mo), A217-C5 (5Cr–1⁄2Mo), A217-C12 (9Cr–1Mo), A352-LCB (Carbon Steel), A352-LCC (Carbon Steel), A351-CF8M (18Cr–9N)

The globe valve is built to handle low temperatures and cryogenic conditions. It is equipped with an extended bonnet, wherein the length will depend on the nature of the application and the specifications of the user. The extended bonnet keeps the stem packing at enough distance away from the cryogenic fluid.

A cryogenic globe valve is often used in gas/terminal production plants, ethylene plants, and LNG (liquefied natural gas). It is also used to throttle cryogenic fluids with temperatures of at least -196°C. TIX provides more well-performanced globe valves for your different applications.

| Temperature | Below -190°C |

|---|---|

| Design and Manufacturing Standards | BS 1873 |

| Face to Face Standards | ASME B16.10 |

| Flange Dimension Standards | ASME B 16.5, ASME B16.47 |

| Pressure Test Standards | API598 |

| Fugitive Emissions | ISO 15848-1, API 622 |

| NACE | NACE MR 0103 NACE MR 0175 |

| Valve operator options | Handwhel, Worm Gear, Electric actuator, Pneumatic actuator, Hydraulic Actuator |

| Process Connection Types | RF, RTJ, BW |