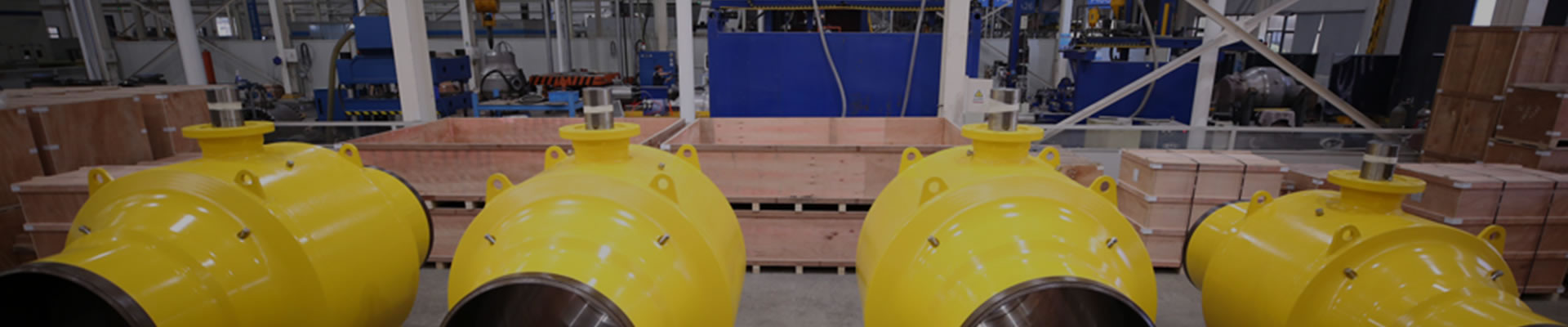

Cryogenic Check Valve

- Pressure Rating

- CL150~CL1500

- Connection

- BW, RF,RTJ

- Design Standard

- API594 BS6364 GB/T24925

- Material

- Stainless Steel

The cryogenic check valves designed by us are suitable for working temperature of -196 ℃. By adopting the most advanced design concept, high precision processing control and strict process management, the ultra-low temperature valve has many outstanding advantages, such as reliable sealing, high stability at low temperature and long service life, etc. Products are widely used in liquefied natural gas, liquefied petroleum gas, air separation and other low-temperature industries.

Size: 2"- 24"/ DN50-DN600

Pressure: CL150-CL1500

- End Connection: Butt weld, Flanged, RTJ

- Standard: API594 BS6364 GB/T24925

- Type: Swing Check, Piston Check, Wafer Type

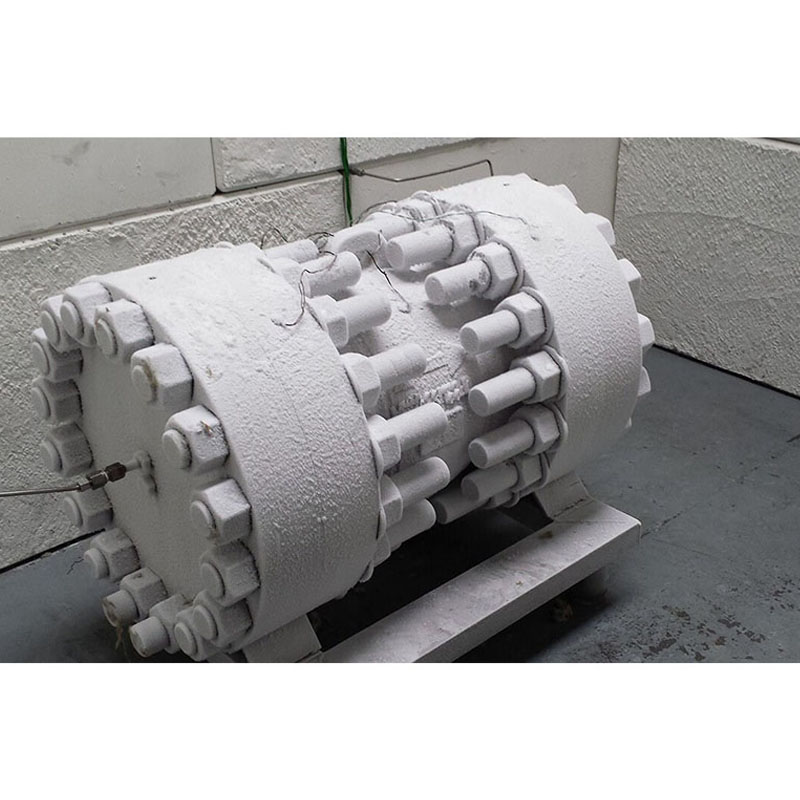

Design Features:

Extended bonnets with sufficient gas column length, usually specified by customer, are supplied for all valves to keep stem packing at sufficient distance away from the cold fluid to remain functional.

Flexible wedges with Stellite seating faces for cryogenic service.

Neoflon inserts are available for swing check discs.

Cleaning: All cryogenic valves are thoroughly degreased and cleaned and pipe ends are sealed to prevent contamination.

Application:

Approved for air gases, vapours and cryogenic liquefied gases, like LNG.