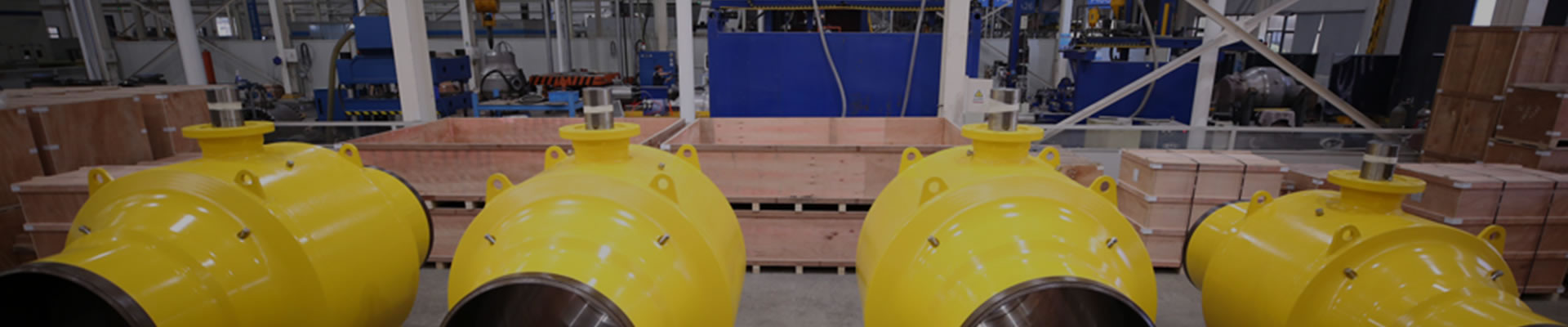

Double Block and Bleed Ball Valves

- Pressure Rating

- CL150~CL2500

- Design Standard

- API 6D, API 608

- Material

- A105N, A105+ENP, F304 (L), F316 (L), LF2, F11, F51

Double Block and Bleed valves (DBB ball valve) assure double isolation function thanks to two obturator inserted in a single body and they provide the bleed function by means of a bleed/vent system located btween obturators (body port and ball, gate or needle valve), from the floating ball valve design, our TIX has several different constructions. Double fixed balls hinge on supports, and floating metal or soft seats, central needle vent valve

Ball valve can be designed into a fire structure, when in case of fire and the sealing ring burned, each sealing parts of the ball valve can form a metal to metal hard sealing structure, effectively prevent the diffusion of the medium, prevent the expansion of fire.

Ball valve can be designed anti-static structure, that is, the ball and stem, stem and valve body between the conductive spring, so that the valve in the process of opening the static electricity generated through the set of the static channel into the pipeline into the underground, to achieve the purpose of removing static electricity. Avoid electrostatic lighting flammable medium to ensure system safety.

The installation in the field or to prevent non-staff misoperation, as well as in some large occasions of vibration by the impact of the handle is easy to produce misoperation of the valve, in the valve fully open or fully closed position without locking hole, when necessary, can be locked, play a role in safety insurance.

Specifications

|

Size Range |

Body Material |

|

1/2"-10" DN15-DN250 |

A105N, F304 (L), F316 (L), LF2, F11, F51 |

|

Pressure Rating |

Ball Material |

|

Class150-Class2500 PN16-PN425 |

A105+ENP, F304 (L), F316 (L), F51, etc. |

|

End Connection |

Seat Material |

|

Flange (RF, RTJ), BW, SW, BSPT, NPT |

(R) PTFE/ NYLON/ PEEK/ PPL |

|

Structure Style |

Stem Material |

|

Full Port, Floating Ball |

F6a, 304 (L), 316 (L) |

|

Actuator Options |

Design Standard |

|

Lever, Worm Gear, Pneumatic, Electric |

API 6D / API 608 |

|

Temperature Range |

Face to Face Standard |

|

-46℃~550℃ |

ASME B16.10, GB/T 12221, GB/T 15188.1 |

|

Connection Standard |

Test Standard |

|

Flange Drilling: ASME B16.5 Butt Weld: ASME B16.25 |

API 598 |