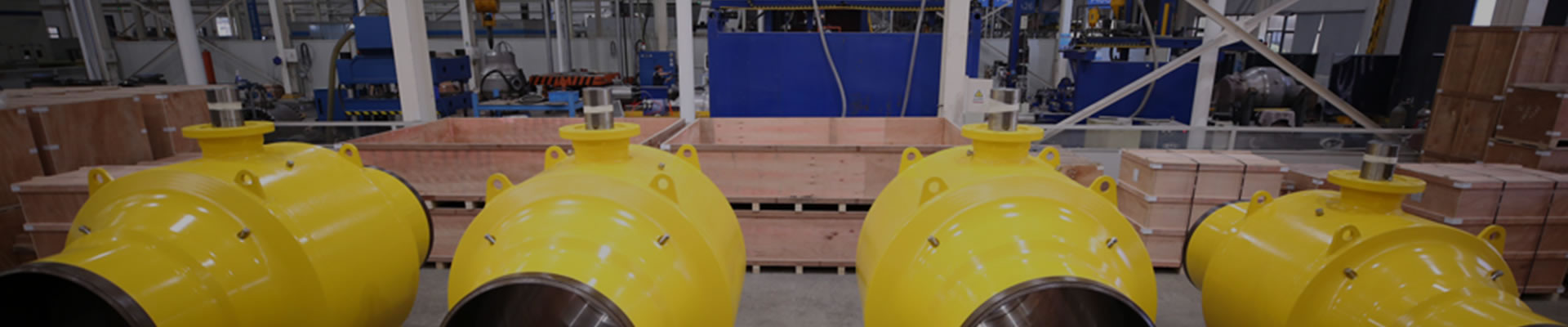

Cryogenic Ball Valve

Cryogenic ball valves are valves that applied at low temperatures. They are built to withstand temperatures as low as -190°C to absolute zero (-238°F to -460°F ) and are thus also known as low temperature ball valves. They are equally capable of handling extremely high pressures that result from such extreme temperatures.Our cryogenic ball valve consists of 3 parts: an actuator, a stem, and a ball. The actuator is the outermost part for which we offer a variety of designs. It is connected to the stem which is a rod-like structure that houses the floating ball. When the actuator is turned, the stem also rotates and repositions the ball accordingly.

Cryogenic Ball Valve Features

● The fluid resistance is small, and the sealing surface is less attacked by the media.

● Open and close less effort.

● The flow direction of the medium is not restricted, not disturbing the flow, not reducing the pressure.

● Simple shape, short structure length, good manufacturing technology, wide range of application.

Specifications

|

Size Range |

Body Material |

|

1/2"-40" DN15-DN1000 |

F304, F316, F316L, LF2 |

|

Pressure Rating |

Ball Material |

|

Class150-Class2500 PN16-PN425 |

F304, F316, F316L, LCB |

|

End Connection |

Seat Material |

|

Flange (FF, RF, RJ), Butt Welding, NPT, SW |

PCTFE |

|

Structure Style |

Stem Material |

|

Full Bore, Reduced Bore Floating Ball, Trunnion Mounted Ball |

XM-19 |

|

Actuator Options |

Design Standard |

|

Handwheel, Pneumatic, Electric |

API 6D |

|

Temperature Range |

Face to Face Standard |

|

-196℃~-460℃ |

ASME B16.10 |

|

Connection Standard |

Test Standard |

|

Flange Drilling: ASME B16.5 Butt Weld: ASME B16.25, GB/T 12224 |

API 598 |